Construction Progress 2019

NOVEMBER 2019

The B17 SLT engineering team have commenced discussions with potential partners for the various items of the rolling chassis prior to placing orders, while we await Ricardo Rail Ltd. of Derby's approval of the design definition for this next phase and other required documentation.

Primarily these are the Horn Blocks, the Cannon Axle boxes, Axles, Tapered Roller Bearings, Driving Wheels and Tyres.

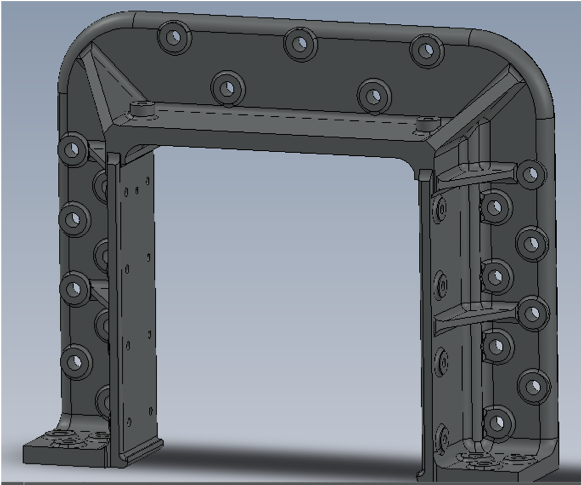

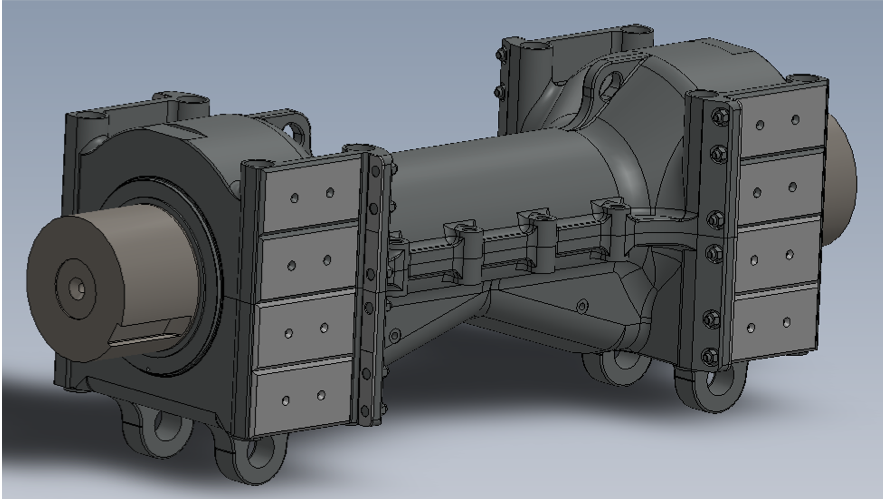

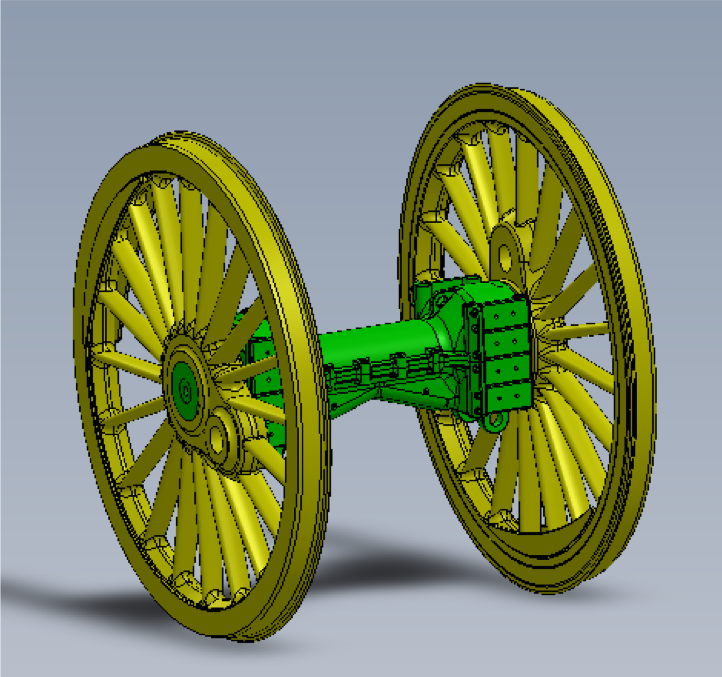

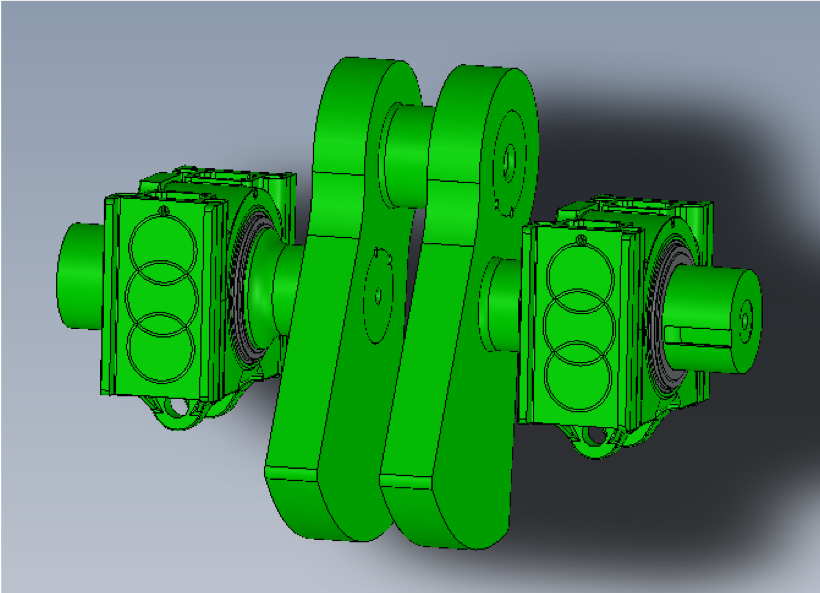

Examples of the CAD drawings are shown here.

|

Hornblock |

| Intermediate and Trailing Cannon Axlebox |  |

|

Intermediate and Trailing Coupled Wheelset showing Cannon Axlebox |

| Crank Axle Assembly showing Roller bearings in Axleboxes |  |

SEPTEMBER 2019

With the completion and approval of the static mainframe, the engineering effort is now concentrating on the rolling chassis. The rolling chassis combines the static mainframe and all parts associated with each axle set for each pair of coupled wheels.

The introduction of a brand new LNER class B17 steam locomotive, to the modern mainline network, is considered as a significant change by the Rail Authority. The B17 SLT must therefore comply with the statutory requirement for undertaking a full and sufficient risk assessment, to identify potential problem areas and corresponding mitigations, subject to independent assessment to ensure that safe working methods and results have been obtained.

The design is complete and formally issued into B17 Build Standard. The full design and manufacturing proposal is to be submitted to Ricardo Rail for approval. Suppliers have been identified and RFQ's will be issued after approval, followed by purchase orders issued against agreed quotations. The design definition has already been shared with Llangollen in discussions on the construction.

The B17 design definition for the rolling chassis describes each axle set in terms of material specifications and dimensions/tolerances for machining and assembly requirements. When the design submission is approved the full kit of parts must be obtained, first to enable each axle set to then be assembled in its own right. The only exception to this relates to the horn blocks and horn stays which can be fitted directly to the frames.

Stress analysis of the crank axle assembly has been identified in the initial risk assessment record log to define loads and stresses covering the full operating envelope of the engine. Much of the design has been derived from Tornado and the P2 (2007) where the help of the A1 Steam Locomotive Trust and David Elliott is acknowledged with our grateful thanks.

MAY 2019

Whilst we wait for the design approval and can start ordering the first components for the rolling chassis (the Hornblocks and Horn Stays) we have started to investigate supplies for components such as the Cab and the Smoke Box. Following our philosophy of using, where possible, local suppliers, we have had preliminary discussions to get indicative cost and to appraise material availability/sizes/form + sections against the LNER drawings, bearing in mind differences between preferred sizes imperial and metric and obsolescence.

SPRING 2019

Rolling Chassis Final Design

The B17 Steam Locomotive Trust (B17 SLT) is pleased to be able to report significant progress on the final rolling chassis design. These are in the process of being finalised with meetings next week and will lead to submission of the rolling chassis design to the Rail Regulator for evaluation.

Static Chassis Complete and Approved

The B17 Steam Locomotive Trust (B17 SLT) is delighted to announce that its static chassis has been approved.

A successful inspection was completed of the mainframe structure at Llangollen on Thursday 21st February by Eddie Draper of Ricardo Rail Ltd, when torque tightening of fasteners was demonstrated to ensure that frame stays were fully secured between the frames. Dimensions between the frames were checked and verified. Ricardo Rail Ltd indicated their acceptance of the structure presented jointly by the Llangollen Team and the B17SLT. Thanks are expressed to Eddie Draper of Ricardo Rail Ltd and the Llangollen Team for their work in achieving this conclusion by the B17 project.

|

Completed Chassis mounted on stands for final inspection and sign off |

| Llangollen team in action - Torque tightening |  |

|

The Inspector, Eddie Draper, and our Chairman, Brian Hall, discussing a technical point |